Choosing the Right Sheep Handler for Your Flock Size

Choosing the right sheep handler is one of the most important decisions you’ll make when upgrading your sheep handling equipment. A good handler reduces labour, improves safety, speeds up routine tasks and supports better flock management. But with so many options available – from manual handlers to automatic systems and integrated weighing setups – it can be difficult to know which one is right for your flock size and workload.

This guide breaks down the key considerations to help you choose the best handler for your farm.

Why Your Sheep Handler Matters

A sheep handler is the heart of your sheep handling system. It affects:

- Throughput

- Labour requirements

- Animal welfare

- Operator safety

- Accuracy of dosing and inspection

- Long‑term flock performance

Choosing the right one ensures your Sheep Yards – Flock Management system works smoothly and efficiently.

1. Start With Your Flock Size

Small Flocks (Up to 150 sheep)

You need a handler that is:

- Affordable

- Compact

- Easy to move

- Simple to operate

A basic manual handler or tipping unit is usually enough. You don’t need automation – you need practicality.

Medium Flocks (150–500 sheep)

You need:

- A robust, reliable handler

- Good restraint for dosing and dagging

- Optional weighing integration

- Compatibility with Sheep Races and Sheep Hurdles

A mid‑range handler with optional loadbars is ideal.

Large Flocks (500–1,500 sheep)

You need:

- High throughput

- Strong, durable construction

- One‑person operation

- Integration with Weighing and EID Systems

- Smooth flow through your sheep handling system

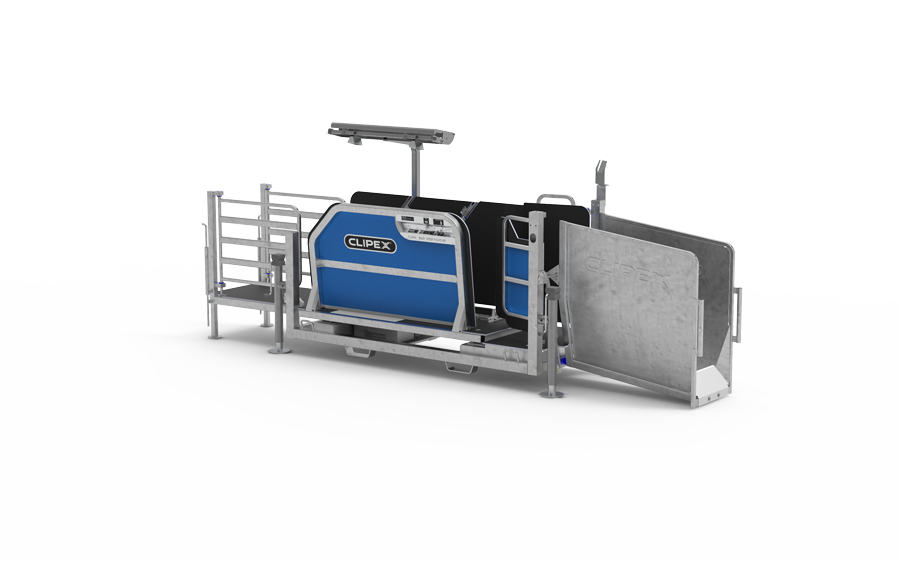

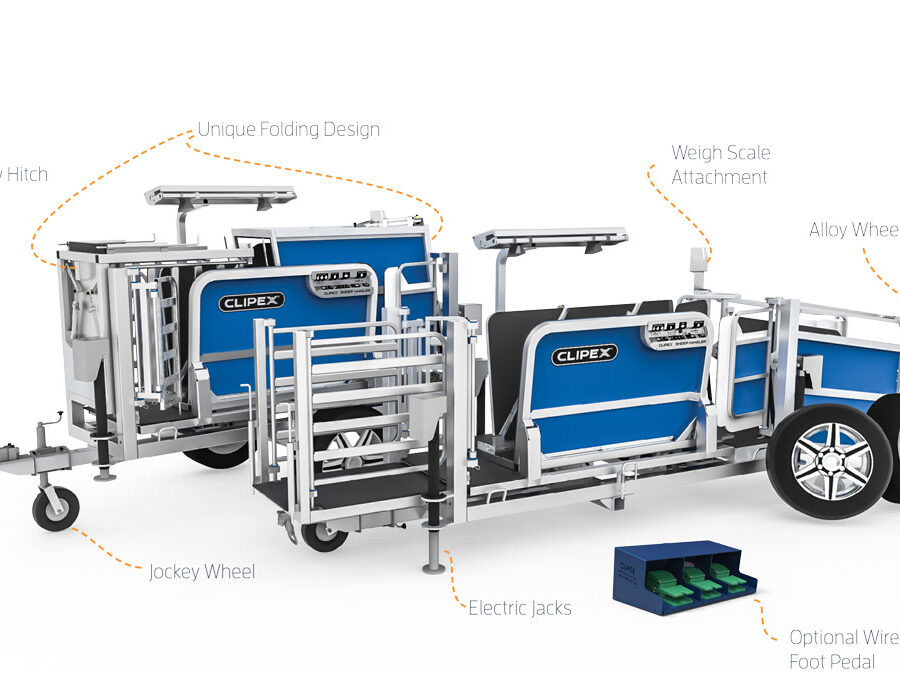

A premium handler like the Clipex Sheep Handler is ideal.

Very Large Flocks (1,500+ sheep)

You need:

- Automation

- Pneumatic or powered operation

- Full EID integration

- Compatibility with auto drafting

- Heavy‑duty build quality

This is where a handler + auto drafter combination becomes essential.

2. Consider the Type of Work You Do Most

Dosing & Vaccinating

You need a handler with:

- Strong side access

- Good head control

- Smooth entry and exit

Dagging & Crutching

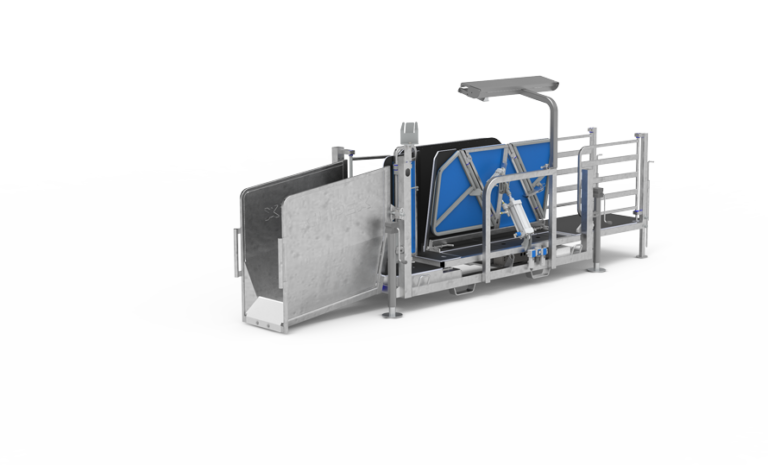

You need:

- A tipping or rollover function

- Secure restraint

- Good operator access

Weighing

You need:

- Loadbar compatibility

- EID Reader integration

- Stable, accurate platform

Foot Checks

You need:

- Safe tipping

- Good leg access

- Non‑slip flooring

High‑Volume Drafting

You need:

- A handler that integrates with an auto-drafter

- Fast reset times

- Smooth sheep flow

3. Labour Availability

One‑Person Operation

If you often work alone, choose a handler with:

- Automatic entry gates

- Easy reset

- Smooth flow

- Minimal physical effort

Two‑Person Teams

You can use a simpler handler, but efficiency still matters.

Seasonal Labour

If you rely on temporary help, choose a handler that is:

- Intuitive

- Safe

- Easy to learn

4. Yard Layout & Mobility

Permanent Yards

Choose a heavy‑duty handler that integrates with:

- Sheep Yard Components

- Sheep Races

- Forcing pens

- Drafting lanes

Mobile Setups

Choose a handler that is:

- Lightweight

- Easy to tow or move

- Quick to set up

5. Integration With Weighing & EID Systems

Modern flock management relies on data. If you want to future‑proof your system, choose a handler that integrates with:

- Tru‑Test loadbars

- Gallagher weigh scales

- EID Stick Readers

- EID Tag Readers

- Panel readers

- Farm software

This allows you to track:

- Growth rates

- Condition scores

- Medicine use

- Breeding performance

- Sale readiness

6. Build Quality & Durability

Look for:

- Galvanised steel

- Strong welds

- Smooth edges

- Quiet operation

- Non‑slip flooring

- Reliable locking mechanisms

A handler should last 10–20 years, not 2–3.

7. Budget & Long‑Term Value

A handler is an investment. Consider:

- Labour savings

- Reduced injuries

- Faster throughput

- Improved accuracy

- Better welfare

- Grant eligibility

Many handlers qualify for:

- FETF Grant (England)

- Small Grants Efficiency (Wales)

- FBIS (Northern Ireland)

- PSF (Scotland)

Choosing the right sheep handler depends on flock size, workload, labour availability and long‑term flock management goals. Small flocks need simplicity. Medium flocks need versatility. Large flocks need throughput and integration. Very large flocks need automation.

A well‑chosen handler becomes the backbone of your sheep handling system — saving time, reducing labour and improving welfare for years to come.