Heavy‑Duty Cattle Crushes: Are They Worth It? A Cost‑Benefit Breakdown for UK Farms

Are heavy-duty cattle crushes worth it? – Investing in a cattle crush as part of their cattle handling equipment is one of the most important decisions a livestock farmer will make. It affects safety, efficiency, labour, animal welfare, and long‑term profitability. But with so many options on the market, from standard manual crushes to premium heavy‑duty models like the Clipex HD and Clipex HDX Series, it’s natural to ask the question: are heavy‑duty cattle crushes really worth the extra investment?

For many UK beef and dairy farms, the answer is increasingly yes. As cattle get larger, labour becomes tighter, and handling demands grow, the benefits of a heavy‑duty crush often outweigh the initial cost. This guide breaks down the real‑world advantages, the financial implications, and the situations where stepping up to a heavy‑duty model makes the most sense.

What Makes a Crush “Heavy‑Duty”?

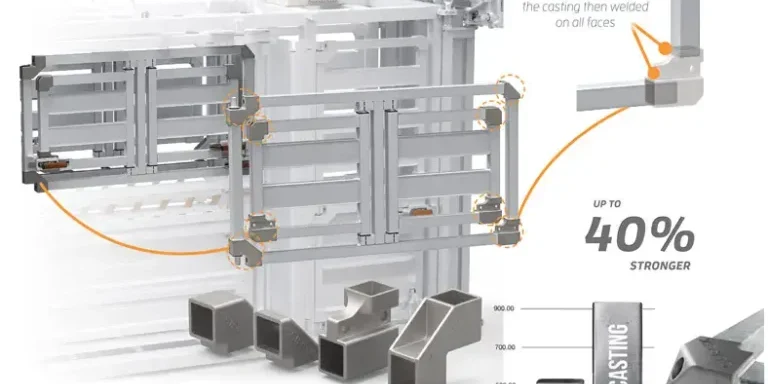

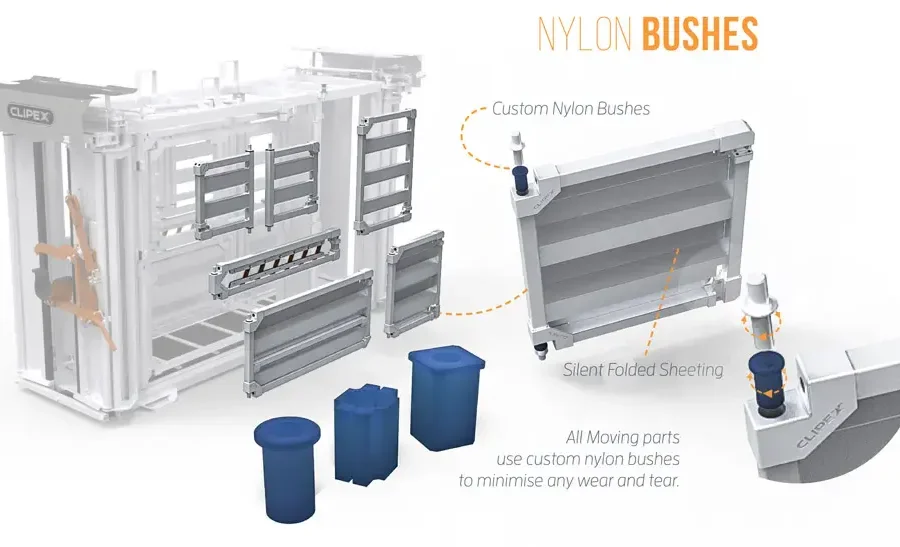

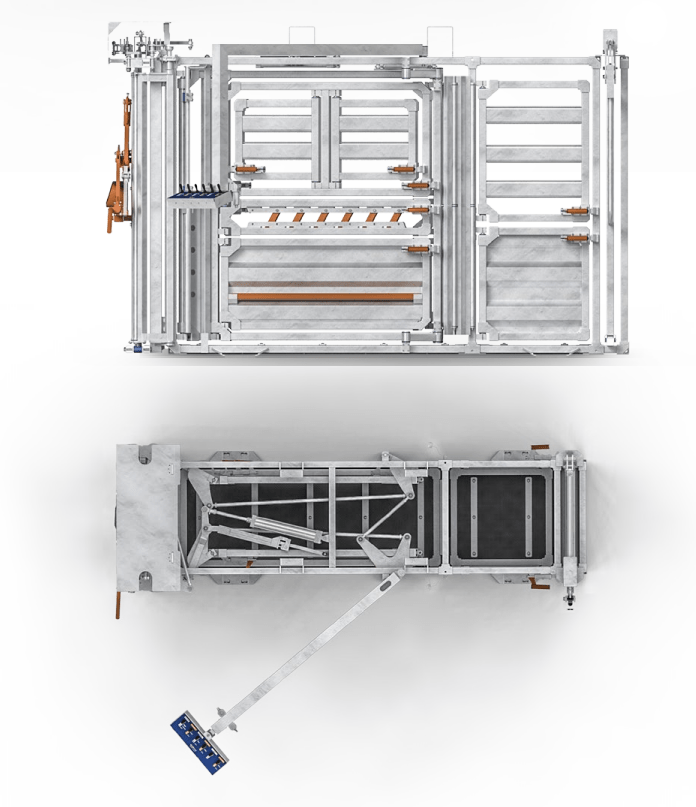

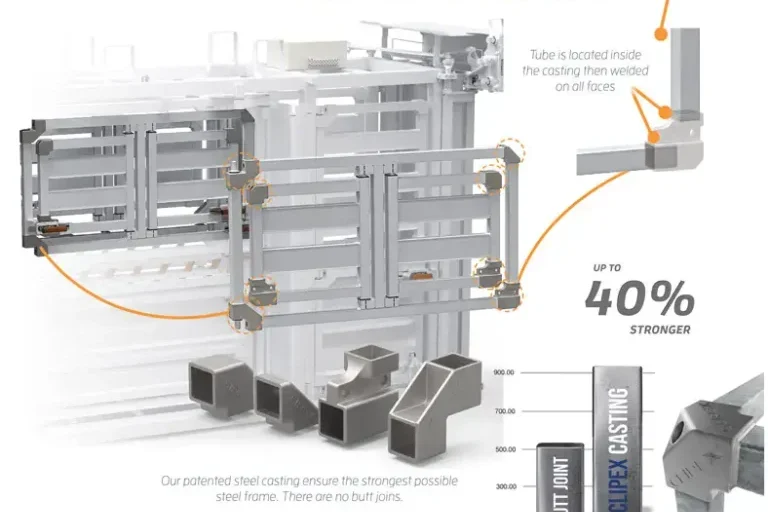

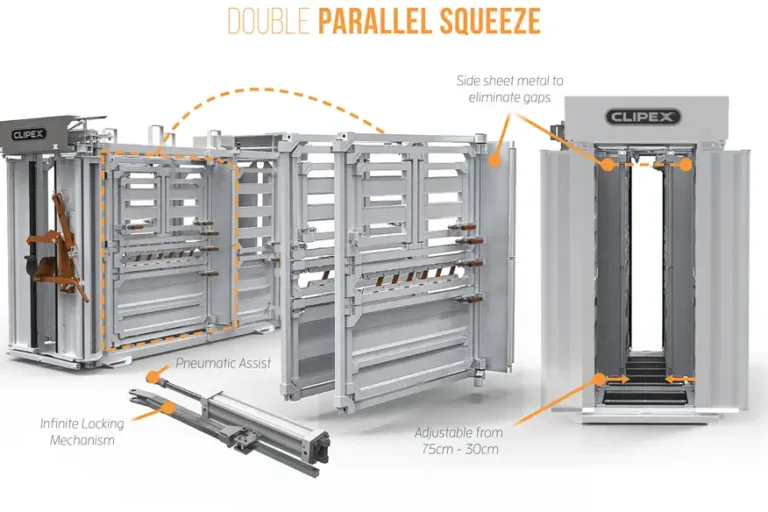

A heavy‑duty cattle crush isn’t just a stronger version of a standard model – it’s engineered for high‑pressure, high‑frequency handling. Key features typically include:

- Reinforced steel frames and uprights

- Stronger welds and structural bracing

- High‑strength head bails

- Anti‑backing systems designed for powerful cattle

- Quiet, low‑stress latching mechanisms

- Optional hydraulic operation

- Enhanced side access for veterinary work

- Longer service life under heavy use

In ranges like the Clipex HD or HDX Series, these upgrades translate into crushes that can withstand years of demanding work with minimal wear.

Why Heavy‑Duty Crushes Are Becoming More Popular in the UK

UK cattle have changed. Modern beef breeds, and even dairy cows, are significantly larger and stronger than they were 20 years ago. Handling expectations have also shifted, with more emphasis on:

- TB testing

- Mobility scoring

- Foot trimming

- Routine health checks

- AI and fertility work

- Data collection and weighing

A crush that was “good enough” a decade ago may now struggle to cope with the size, strength, and frequency of handling required.

Cost‑Benefit Breakdown: Are Heavy‑Duty Crushes Worth It?

Let’s look at the real‑world benefits and how they translate into value for UK farms.

1. Safety: The Most Important Factor

A heavy‑duty crush dramatically reduces the risk of injury for both cattle and handlers. Stronger frames, reliable locking systems, and stable construction prevent dangerous movement and reduce the chance of accidents.

Benefits for beef farms

- Better control of large, lively finishing cattle

- Safer handling of suckler cows with calves at foot

- Reduced risk when working with bulls (model‑dependent)

Benefits for dairy farms

- Safer foot trimming and mobility scoring

- Better restraint for large Holsteins and cross‑breeds

- Reduced stress during frequent handling

Financial impact: Avoiding even one serious injury to staff or cattle can justify the cost of a heavy‑duty crush.

2. Durability and Long‑Term Value

Heavy‑duty crushes are built to last. Reinforced steel, stronger welds, and premium components mean they can withstand years of daily use without bending, cracking, or wearing out.

Why this matters

- Standard crushes may need replacing every 5–10 years

- Heavy‑duty crushes often last 15–20+ years

- Lower maintenance costs over time

- Higher resale value

Financial impact: A heavy‑duty crush may cost more upfront, but the cost per year of use is often significantly lower.

3. Efficiency and Labour Savings

Time is money, especially on farms with limited labour. Heavy‑duty crushes both manual crushes and pneumatic crushes, include features that speed up handling and reduce physical effort.

Efficiency benefits

- Faster head bail capture

- Smoother operation

- Better cattle flow

- Hydraulic options reduce operator fatigue

- Improved access speeds up treatments

For dairy farms

Frequent handling (AI, foot trimming, mobility scoring) makes efficiency essential. A heavy‑duty crush with hydraulic operation can save hours every week.

For beef farms

Large groups can be processed faster, reducing cattle stress and improving throughput.

Financial impact: Saving even 10–15 minutes per handling session adds up quickly across a year.

4. Better Animal Welfare

Low‑stress handling is now a priority for both beef and dairy producers. Heavy‑duty crushes are designed with welfare in mind:

- Quiet latches

- Smooth edges

- Non‑slip flooring

- Secure, stable restraint

- Reduced bruising and injury

Calmer cattle move better, handle better, and perform better.

Financial impact: Improved welfare reduces stress‑related losses and improves productivity.

5. Future‑Proofing Your Handling System

A heavy‑duty crush is a long‑term investment that supports future cattle handling system upgrades:

- EID integration

- Weighing systems

- Drafting units

- Hydraulic controls

- Full cattle yard redesigns

Choosing a heavy‑duty model now prevents the need for costly replacements later.

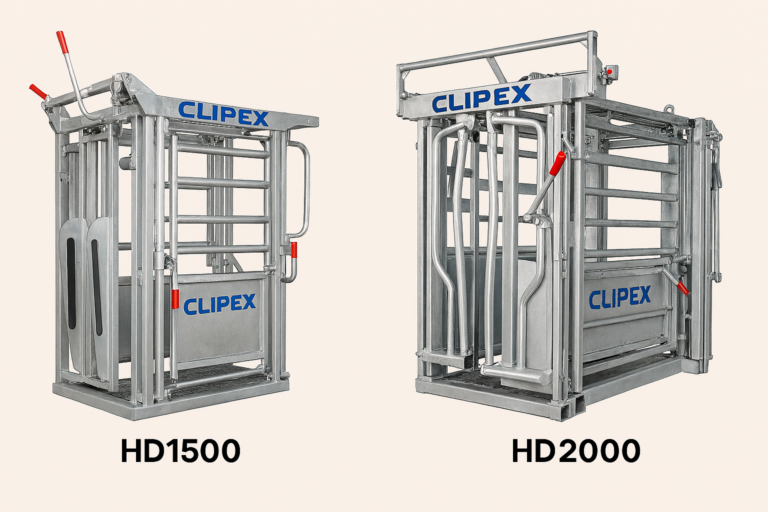

HD vs HDX: Which Heavy‑Duty Crush Is Right for You?

The Clipex HD Series and Clipex HDX Series are two of the most popular heavy‑duty options in the UK. Here’s how they compare:

Clipex HD Series

Best for:

- Small to medium beef farms

- Dairy farms with moderate handling frequency

- Mixed herds

- Farms wanting heavy‑duty strength at a lower price point

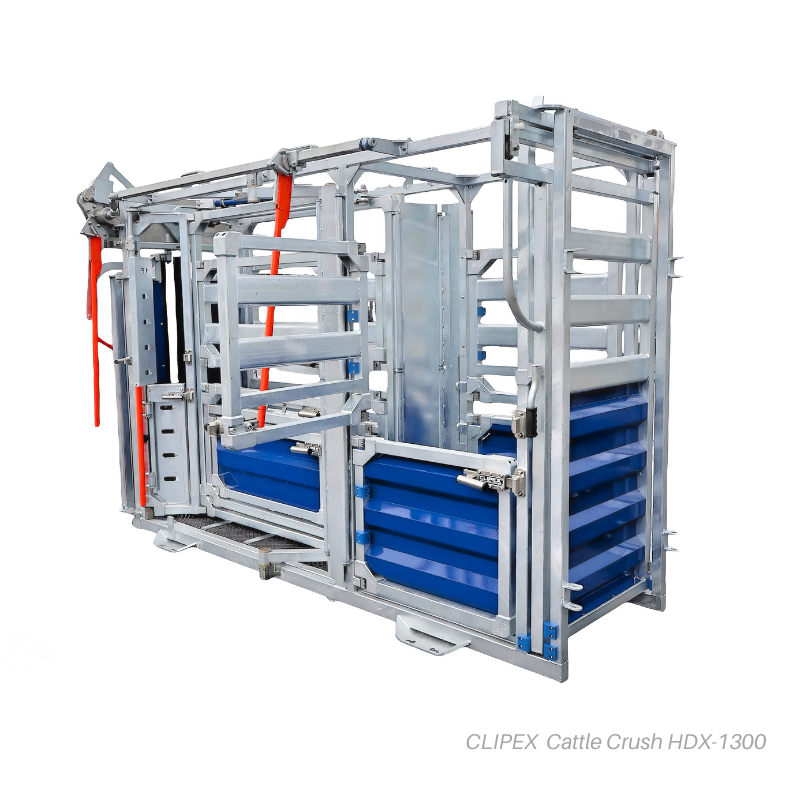

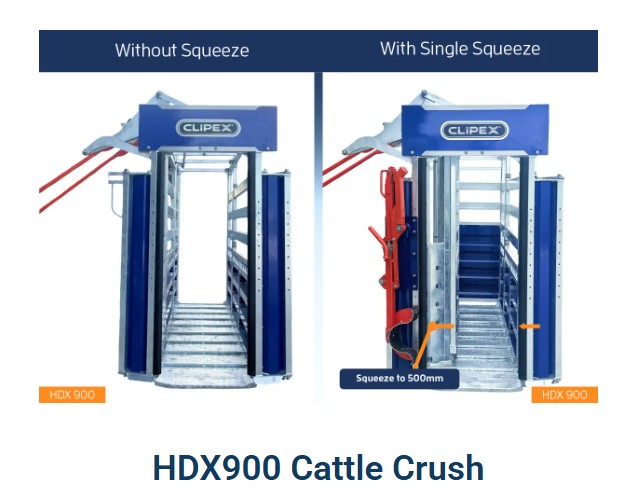

Clipex HDX Series

Best for:

- Large beef finishing units

- High‑throughput dairy farms

- Farms handling big, strong cattle

- Producers wanting hydraulic operation

- Units where speed and safety are top priorities

If you handle cattle frequently, work with large animals, or want a crush that will last decades, the HDX is often the better long‑term investment.

So, Are Heavy‑Duty Crushes Worth It?

For most UK beef and dairy farms, yes, Heavy-duty crushes offer excellent long‑term value. The combination of safety, durability, efficiency, and welfare benefits makes them a smart investment that pays for itself over time.